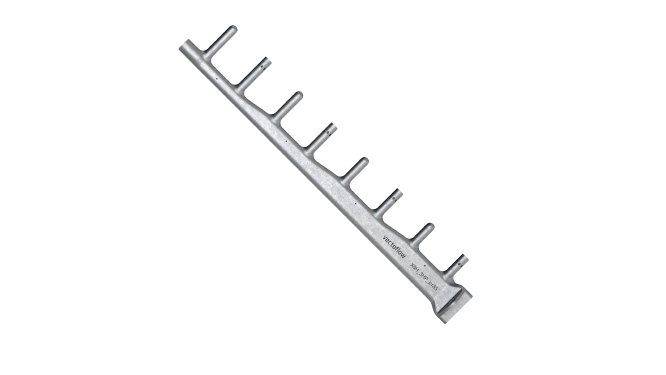

Rakes or probe rakes combine several measuring heads in one probe and are therefore ideal for recording flow variables at several measuring points at the same time. Rakes can be equipped with the following measuring heads: multi-hole, keel total pressure & keel total temperature.

Different probe heads (multi-hole, keel total pressure & keel total temperature) can be combined in a rake or probe rake, thus offering the customer a higher spatial resolution in just a single probe.

Here too, the additive manufacturing process offers great geometric freedom, which allows the rakes to be adapted precisely to the application or to integrate the measuring points into other components and thereby achieve the highest level of mechanical strength.

Vectoflow develops the design of the rakes based on customer requirements and supported by FEM simulations. Furthermore, Vectoflow carries out a variety of verification steps to determine and secure properties such as roughness, geometric accuracy, crack formation (X-ray or FPI examinations), and natural frequencies.

The rakes are also calibrated in Vectoflows own calibration channels.